Historical building renovations require a delicate balance between preserving architectural integrity and incorporating modern performance standards. When selecting steel window profiles for heritage projects, professionals must navigate complex requirements that honor the original design while meeting contemporary energy efficiency and safety codes. The choice of appropriate steel window profiles can make or break the success of a historical renovation, affecting everything from visual authenticity to long-term structural performance.

Heritage buildings present unique challenges that demand specialized solutions. The original fenestration often defines the character and historical significance of these structures, making window replacement decisions particularly crucial. Modern steel window profiles must replicate the slender sight lines and proportions of traditional designs while incorporating advanced thermal performance features that were unavailable in earlier eras. This careful balance requires extensive knowledge of both historical construction methods and contemporary manufacturing capabilities.

Understanding Historical Window Design Principles

Traditional Steel Window Construction Methods

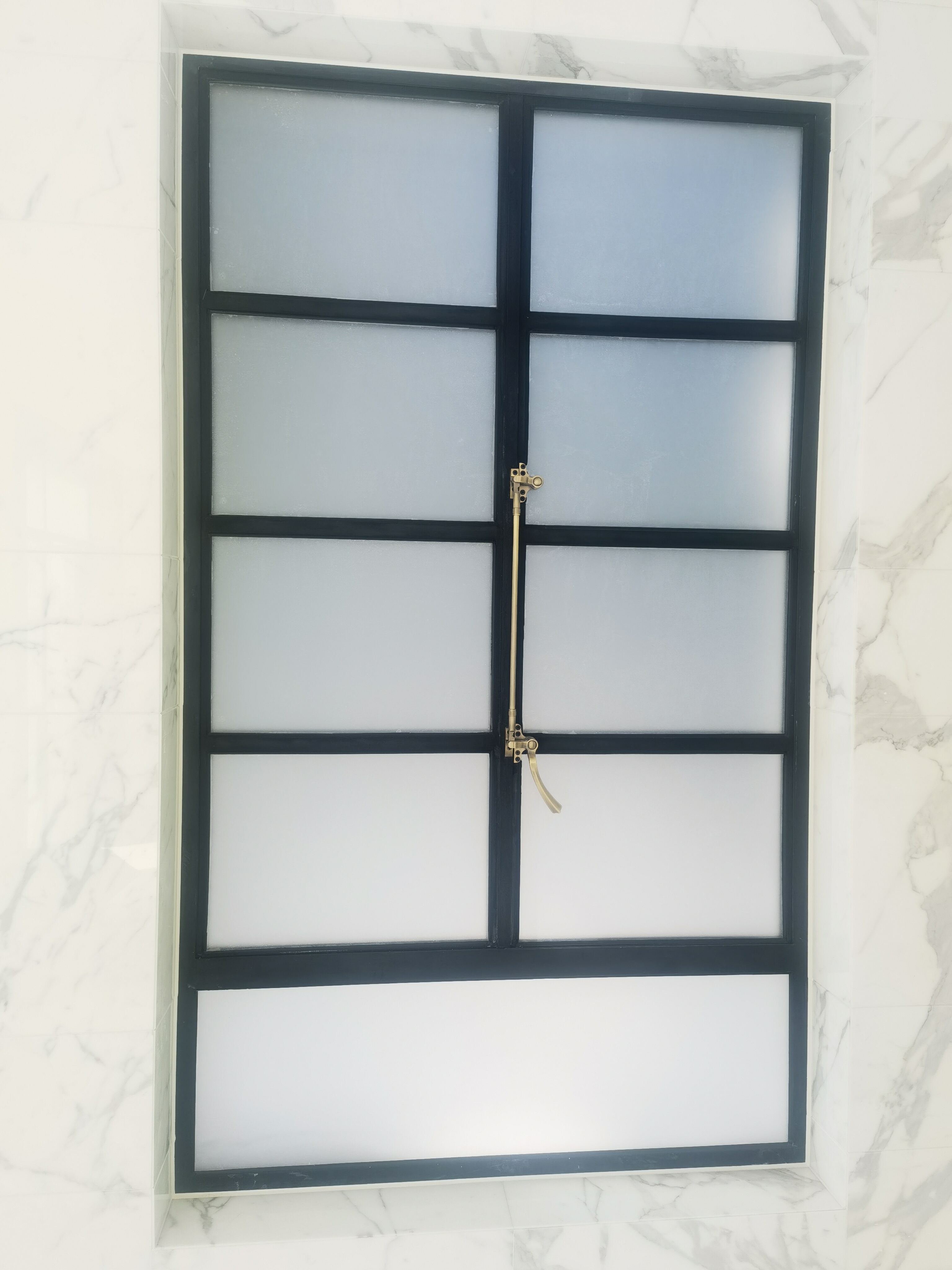

Early steel window profiles were characterized by their minimal frame dimensions and distinctive mullion patterns. These windows typically featured hot-rolled sections with limited thermal breaks, creating the characteristic narrow profiles that defined architectural styles from the Industrial Revolution through the mid-20th century. Understanding these original construction methods is essential for specifying appropriate replacement steel window profiles that maintain historical accuracy.

The manufacturing processes of traditional steel windows created specific visual characteristics that modern reproductions must replicate. Original profiles often displayed subtle variations in section dimensions and surface textures that contributed to their authentic appearance. Contemporary steel window profiles designed for historical applications must account for these nuances while incorporating modern performance enhancements seamlessly.

Architectural Style Considerations

Different architectural periods established distinct window design conventions that influence steel window profiles selection. Art Deco buildings favored geometric patterns and streamlined profiles, while Industrial architecture emphasized functional grid systems with robust framing members. Victorian-era structures often incorporated elaborate glazing patterns that required specialized steel window profiles to accommodate complex geometries.

Regional architectural traditions also impact steel window profiles requirements. European industrial buildings typically featured different proportional relationships compared to American factory structures, necessitating careful research into period-appropriate specifications. This historical context guides the selection process for steel window profiles that will maintain the building's architectural integrity while providing modern functionality.

Technical Performance Requirements

Thermal Efficiency Standards

Modern building codes mandate specific thermal performance levels that challenge traditional steel window profiles design. Heritage projects must achieve these standards while maintaining the visual characteristics of historical windows. Advanced thermal break technology allows contemporary steel window profiles to meet energy codes without significantly altering their appearance from the exterior.

Condensation control represents another critical consideration when specifying steel window profiles for historical renovations. Traditional single-glazed steel windows were notorious for condensation issues, but modern double or triple-glazed units within historically accurate steel window profiles can eliminate these problems. The key lies in selecting profiles that accommodate high-performance glazing while maintaining appropriate sight line dimensions.

Structural Integration Challenges

Historical masonry and structural systems require careful consideration when installing new steel window profiles. Original window openings may have settled or shifted over decades, necessitating custom fabrication to ensure proper fit and weatherproofing. The connection details between steel window profiles and existing structural elements must account for differential movement and thermal expansion.

Load transfer mechanisms in heritage buildings often differ from modern construction standards. Steel window profiles must integrate with existing structural systems without compromising the building's stability or historical fabric. This may require specialized anchoring systems or reinforcement strategies that work within the constraints of protected historical structures.

Material Selection and Durability

Steel Grade and Coating Systems

The selection of appropriate steel grades for historical window profiles impacts both longevity and maintenance requirements. Modern steel formulations offer superior corrosion resistance compared to traditional materials, extending service life significantly. However, the coating systems applied to steel window profiles must be compatible with historical preservation standards and provide long-term protection.

Galvanizing processes and powder coating technologies enhance the durability of steel window profiles while maintaining their historical appearance. These protective treatments must be carefully selected to avoid altering the visual characteristics that define the building's historical character. The finish quality of steel window profiles directly impacts both aesthetic authenticity and long-term performance in challenging environmental conditions.

Environmental Resistance Features

Historical buildings often face severe environmental challenges that demand robust steel window profiles. Coastal locations subject windows to salt spray corrosion, while urban environments expose them to pollution and temperature cycling. The steel window profiles selected must demonstrate proven resistance to these conditions while maintaining their appearance over extended service periods.

Weather sealing systems integrated into steel window profiles must provide superior protection without compromising historical accuracy. Traditional windows often relied on simple overlap joints that are inadequate for modern performance standards. Contemporary steel window profiles incorporate advanced sealing technologies that are concealed within the profile geometry, maintaining historical appearance while providing modern weather resistance.

Installation and Restoration Considerations

Preservation Guidelines Compliance

Heritage preservation authorities establish strict guidelines governing modifications to historical buildings. Steel window profiles specifications must comply with these requirements while achieving functional improvements. The approval process often requires detailed documentation demonstrating how proposed steel window profiles maintain the building's historical character and significance.

Documentation requirements for historical projects demand comprehensive records of existing conditions and proposed modifications. The selection of steel window profiles must be supported by historical research and technical analysis that demonstrates appropriateness for the specific building and time period. This documentation becomes part of the permanent record for future preservation efforts.

Custom Fabrication Requirements

Most historical renovations require custom fabrication of steel window profiles to match original dimensions and configurations. Standard manufacturing profiles rarely accommodate the unique proportions and details found in heritage buildings. Custom fabrication capabilities become essential for producing steel window profiles that replicate historical designs while incorporating modern performance features.

Quality control processes for custom steel window profiles must ensure consistent replication of historical details across multiple units. Dimensional accuracy, surface finish quality, and hardware compatibility all require careful monitoring throughout the fabrication process. The complexity of custom steel window profiles often necessitates specialized manufacturing capabilities and extended lead times.

Cost Analysis and Project Planning

Budget Considerations for Heritage Projects

Historical renovation budgets must account for the premium costs associated with custom steel window profiles and specialized installation requirements. The complexity of heritage projects typically results in higher material and labor costs compared to standard commercial applications. However, the long-term value preservation achieved through appropriate steel window profiles selection often justifies these initial investments.

Funding sources for historical projects may include grants and tax incentives that offset the costs of premium steel window profiles. These programs often require compliance with specific preservation standards that influence material selection and installation methods. Understanding available funding options can significantly impact the feasibility of comprehensive steel window profiles replacement in heritage buildings.

Lifecycle Cost Evaluation

The total cost of ownership for steel window profiles in historical applications extends beyond initial purchase and installation expenses. Maintenance requirements, energy performance, and replacement intervals all contribute to long-term costs. High-quality steel window profiles with superior durability and thermal performance often provide better lifecycle value despite higher upfront costs.

Energy savings achieved through modern steel window profiles can substantially offset their initial costs over time. Improved thermal performance reduces heating and cooling loads, while enhanced weather sealing eliminates air infiltration losses. These operational savings accumulate over the extended service life expected from quality steel window profiles installations.

Specification and Procurement Process

Technical Drawing Requirements

Comprehensive technical drawings are essential for successful steel window profiles procurement in historical projects. These drawings must capture all dimensional requirements, hardware locations, and installation details specific to the heritage building. The accuracy of these specifications directly impacts the quality and fit of the finished steel window profiles.

Coordination between architectural drawings and structural requirements ensures that steel window profiles integrate properly with existing building systems. This coordination process often reveals conflicts that require design modifications before fabrication begins. Early identification of these issues prevents costly delays and field modifications during installation.

Vendor Selection Criteria

Selecting appropriate manufacturers for historical steel window profiles requires evaluation of specialized capabilities and experience. Not all steel window manufacturers possess the expertise necessary for heritage project requirements. The chosen vendor must demonstrate proficiency in custom fabrication, historical replication, and quality control processes specific to steel window profiles for heritage applications.

Quality assurance programs become particularly important when procuring steel window profiles for historical renovations. The manufacturer's testing procedures, material certifications, and quality control systems must ensure consistent production of profiles that meet both performance standards and historical accuracy requirements. This quality focus prevents delays and ensures successful project completion.

FAQ

What makes steel window profiles suitable for historical building renovations

Steel window profiles offer the ideal combination of slender sight lines, structural strength, and customization capabilities required for historical renovations. Unlike other materials, steel can be fabricated to match the precise proportions and details of original historical windows while incorporating modern thermal breaks and weathersealing systems. The durability of steel ensures long-term performance that matches the expected service life of heritage buildings.

How do modern thermal breaks affect the appearance of historical steel window profiles

Contemporary thermal break technology can be integrated into steel window profiles without significantly altering their historical appearance. Advanced thermal break systems are designed to fit within the profile geometry, maintaining the narrow sight lines characteristic of historical windows. The thermal breaks are typically concealed within the frame construction, preserving the authentic visual character while providing modern energy efficiency.

What approval processes are required for steel window profiles in heritage buildings

Heritage building modifications typically require approval from local preservation authorities, historical commissions, or similar regulatory bodies. The approval process involves submitting detailed specifications for the proposed steel window profiles, including drawings, material specifications, and historical documentation. The review focuses on ensuring that the new profiles maintain the building's historical character and comply with preservation guidelines.

How long do quality steel window profiles last in historical applications

High-quality steel window profiles with proper protective coatings and installation can provide service lives of 50 years or more in historical applications. The durability depends on factors such as environmental conditions, maintenance practices, and the quality of the original installation. Premium steel window profiles with advanced coating systems often outperform traditional materials while requiring less frequent maintenance throughout their service life.

Table of Contents

- Understanding Historical Window Design Principles

- Technical Performance Requirements

- Material Selection and Durability

- Installation and Restoration Considerations

- Cost Analysis and Project Planning

- Specification and Procurement Process

-

FAQ

- What makes steel window profiles suitable for historical building renovations

- How do modern thermal breaks affect the appearance of historical steel window profiles

- What approval processes are required for steel window profiles in heritage buildings

- How long do quality steel window profiles last in historical applications